Ka whakamahia te Hiko Kauwhata mo te Whakapai i te Corundum Umu Pewa Hiko Nga Umu Hiko Diameter Iti

Tawhā Hangarau

Tūtohi 1:Tawhā Hangarau Mo Te Hiko Kauwhata Diameter Iti

| Diamita | Wahi | Ātete | Te Kaha Toka | Young Modulus | Kiato | CTE | Te pungarehu | |

| Inihi | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Hikohiko | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Kouma | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Hikohiko | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Kouma | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Hikohiko | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Kouma | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Hikohiko | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Kouma | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Hikohiko | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Kouma | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Hikohiko | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Kouma | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Tūtohi 2: Te Kaha Kawe O Naianei Mo Te Hiko Kauwhata Diameter Iti

| Diamita | Uta o naianei | Kiato o naianei | Diamita | Uta o naianei | Kiato o naianei | ||

| Inihi | mm | A | A/m2 | Inihi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Tūtohi 3: Te Rahi Hiko Kauwhata me te Whakaaetanga Mo te Hiko Kauwhata Diameter Iti

| Diamita Ingoa | Diamita Tuturu(mm) | Te Roa Ingoa | Te manawanui | |||

| Inihi | mm | Max. | Min. | mm | Inihi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Taupānga Matua

- Te whakarewa konupora carbide

- Ko te hanga Carborundum

- Te whakamahine corundum

- Whakarewa konganuku onge

- Ko te tipu Ferrosilicon he aukati

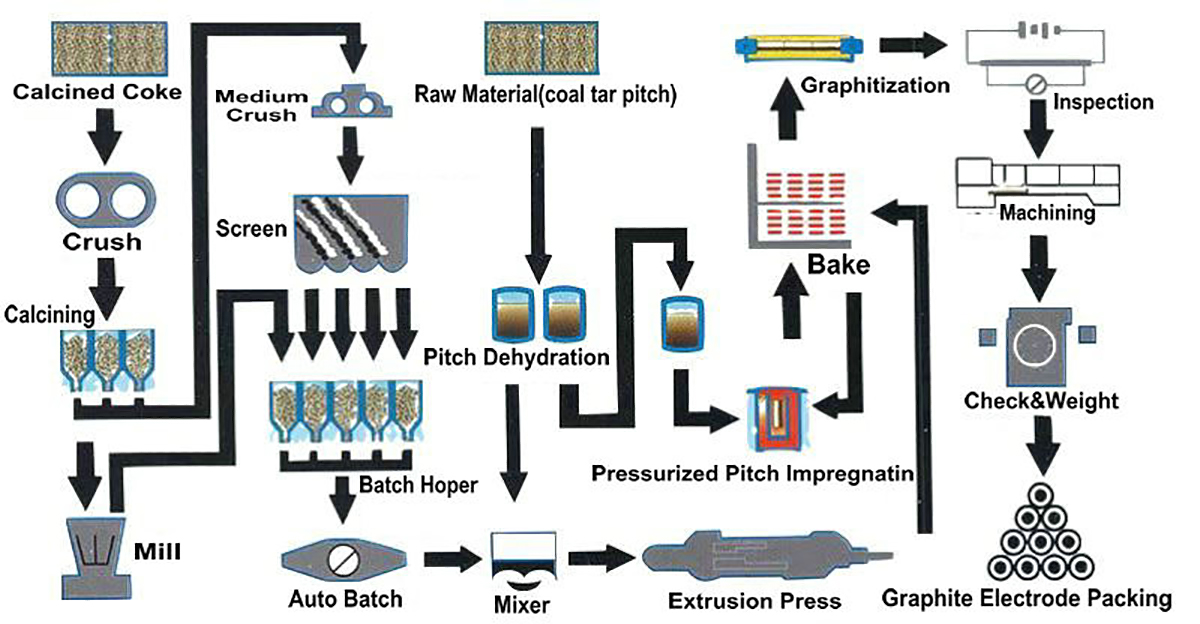

RP Graphite Electrode Process Production

Gufan Painga

1. He mea hanga mai i nga rauemi graphite-kounga teitei, ka hangaia o tatou hikohiko graphite diameter iti ki te tu atu i nga wera nui me te whakarato i te kawe hiko pai. Ma tenei ka whakarite he mahi whakangao me te pai, ka hua te kounga o nga hua me te whakaiti i te whakapau kaha.

2. Ko te iti o te rahi o enei electrodes ka taea te whakahaere tika mo te mahi whakarewa, kia tino pai mo nga tono e hiahia ana kia tino tika me nga hua pai. Ahakoa kei te hanga koe i te koranu, i te para whakarewa ranei, ka awhina a maatau hiko ki te whakatutuki i nga hua e hiahiatia ana me te tino tika.

3. Ko o tatou hiko graphite iti te diameter e pai ana mo te maha o nga ahumahi, tae atu ki te hanga maitai, te tukatuka matū, me te whakarewa whakarewa. Ahakoa te rahi o to mahi, ka taea te whakarite i o maatau hiko ki te whakatutuki i o whakaritenga motuhake.

4. I roto i te hanga maitai, ka whakamahia o tatou hikohiko graphite iti te diameter i roto i nga oumu arc hiko, he waahi nui ta ratou ki te hanga maitai o te kounga teitei. Ko te iti o te rahi ka taea te whakahaere tika i te tukanga whakarewa, te whakarite kia rite nga hua me te whakaiti i nga ururua.

5. I roto i te tukatuka matū, he mea nui o tatou electrodes mo te hanga o te konupūmā carbide me te whakamahine o te carborundum. Ko enei tukanga e hiahia ana kia tika te whakahaere i te pāmahana, e tukuna ana e o maatau hiko me te tino tika.

6. Mo te whakarewanga whakarewa, ka whakamahia o tatou hikohiko kauwhata diameter iti ki te whakarewa i nga konganuku onge me nga tipu Ferrosilicon. Ko te pai o te kawe o te kauwhata ka taea te whakarewa pai o nga konganuku, ka tere ake nga huringa whakaputa me te nui ake o te hua.